Little Known Questions About Motorcycle Parts New Zealand Specialists.

Table of ContentsSome Known Questions About Motorcycle Parts New Zealand Specialists.The Buzz on Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists IdeasWhat Does Motorcycle Parts New Zealand Specialists Mean?Motorcycle Parts New Zealand Specialists for BeginnersMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisNot known Incorrect Statements About Motorcycle Parts New Zealand Specialists Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know

Reach out to one of our experts today.CNC machining innovation is promptly becoming the focal point of lots of various manufacturing procedures around the world as a straight outcome of its numerous benefits over other methods. Additionally, the sectors that manufacture bikes have gotten on board with this pattern. The most innovative companies are now developing their engine components and wheels utilizing machining methods originally developed for motorbike components.

On the various other hand, the impacts of industry are the primary focus of this post. Let's get right right into it. You may be wondering why we make use of. It is not tough to fathom the aspects that caused this result. Now that we have your focus let us explain the reasoning behind this modern growth in the motorbike production market.

The Main Principles Of Motorcycle Parts New Zealand Specialists

On top of that, you have complete control over the look of the parts, also to the min information. Periodically, motorcyclists might make a decision to beautify their ride by setting up aftermarket parts or customizing the bike's remodeling. Once once again, computer system mathematical control (CNC) machining is the most practical technique. Upgrades might be of any type of kind and style you desire.

What Does Motorcycle Parts New Zealand Specialists Do?

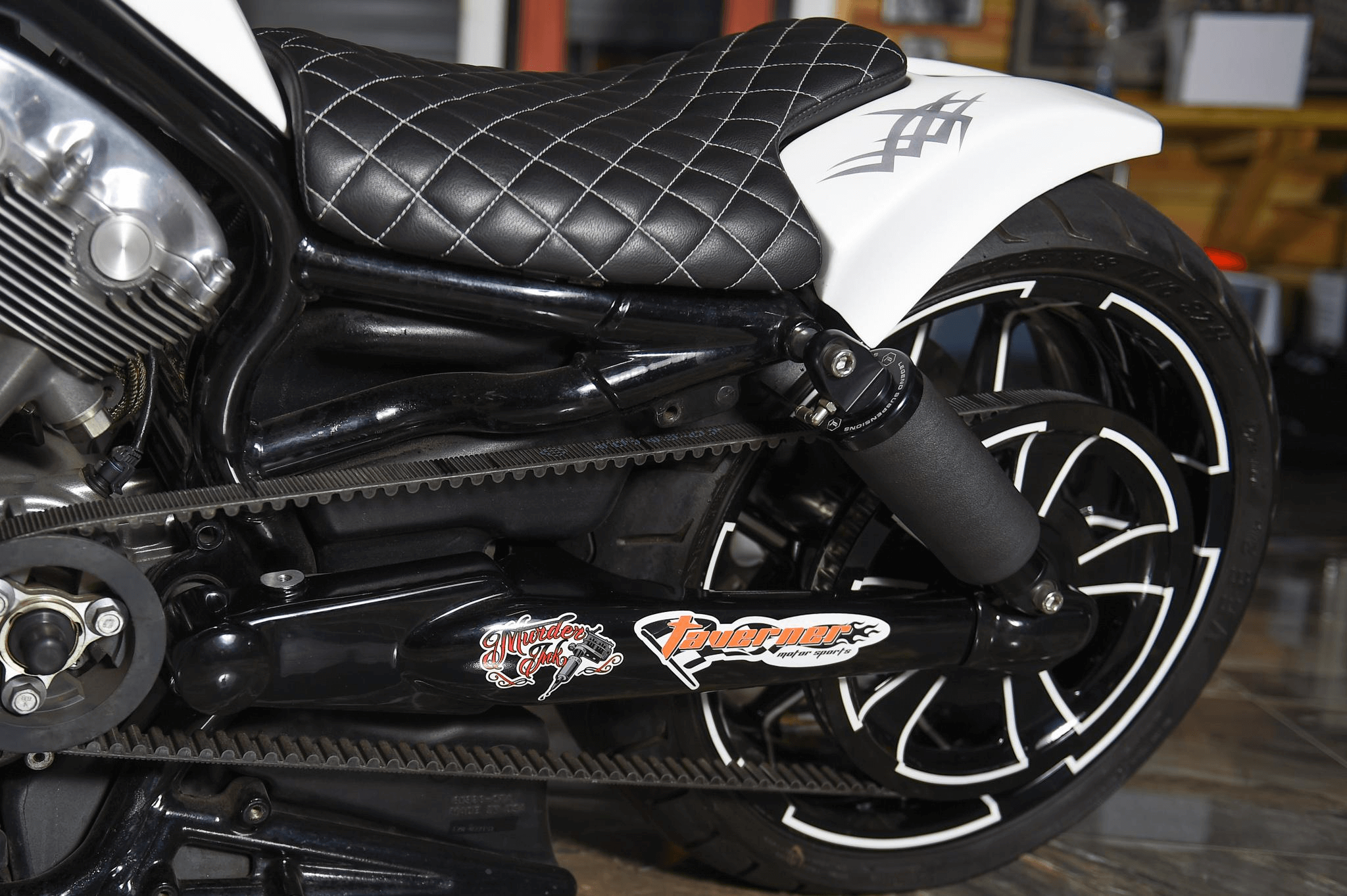

CNC machining may be made use of to make nearly all of a motorcycle's steel and plastic parts. To proceed, we'll talk about a number of machined components for bikes. In comparison to those on cars and trucks, wheels on motorcycles have a tendency to be extra obvious. As an outcome, the bike's looks may be improved with the ideal personalization of these wheels.

When customizing the wheels, the disks are where the focus needs to be. The majority of them are constructed of light weight aluminum. Light weight aluminum alloys are popular for the impressive machining capacities that they have. Milling treatments are made use of to get the desired level of wheel personalization. One more element of the bike that might be individualized is the tires.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

When it concerns a vehicle (or a motorcycle), the most crucial element is the engine. A number of individuals mention it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be intricate and need designs with a high degree of precision.

Usage only top notch products, nevertheless, since these lights are vital for the safety and security of motorcyclists and various other vehicle drivers or people on the roadway, specifically at evening. Motorcycle headlights have 3 major parts: the bulb, or light resource, the lens, and the real estate.

Milling processes with a perfect coating would lead to the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other this article hand, is not made up of fragile materials; instead, it is constructed out of hard polymers that can be machined right into more complex patterns.

Rumored Buzz on Motorcycle Parts New Zealand Specialists

They typically have fancy geometries with a wealth of min details. Motorcycle suppliers usually cast these parts, but just for the manufacturing of bespoke components. CNC machining is the technique of selection when creating unique items. Machining on five axes in today's globe is the ways by which any kind of style shape might be recognized.

Choose Runsom for your personalized bike components! We have the ability to make difficult and elegant elements making your bike unparalleled.

Right here are a couple of examples of steels often used in bike part machining. Aluminum is the primary product utilized by business specializing in creating customized motorcycle parts to develop most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional steel that is really light in weight and has wonderful machining qualities as a result of its high mechanical stamina. This material might be formed into virtually any type of shape and maintains its measurements well. Even mission-critical parts that require a high level of precision may gain from their use.

A Biased View of Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy usage in the production of CNC-customized elements is magnesium. It is among the lightest metals that are now available and has exceptional machinability attributes and toughness proportionate with its reduced weight. Among the downsides of magnesium is that its dirt may easily capture fire.

Their most common usage in creating various bike components is bolts, such as screws and bolts. Their low vulnerability to oxidation and corrosion makes them ideal for this usage.

5 Simple Techniques For Motorcycle Parts New Zealand Specialists

It seems that CNC turning and grating are the fundamental processes. Different techniques exist, such as boring. Allow's investigate numerous of these machining strategies extensive. The CNC turning method is taken into consideration a subtractive manufacturing technique. On top of that, it needs keeping check my blog bars of material, most commonly plastic or steel, in position and after that my link twisting a cutting tool to get rid of sections of the material as the material is turned.

These techniques are equally crucial and generate parts with high precision and constant top quality. The processes aid enhance the general top quality of the machined motorbike parts.

The 6-Minute Rule for Motorcycle Parts New Zealand Specialists

Comments on “The Best Strategy To Use For Motorcycle Parts New Zealand Specialists”